Precision Filter Welding Solution: YAG Laser Welding Technology

Zero Deformation · High Sealing · Micron-Level Precision Control

Industry Pain Points

Traditional welding methods such as argon arc welding and resistance welding often lead to deformation, burn-through, and thermal damage when welding ultra-thin metal filter cores. These issues result in:

-

Reduced filter core sealing performance

-

Deviations in filtration accuracy

-

Difficulty in ensuring high production yield

Innovative Solution

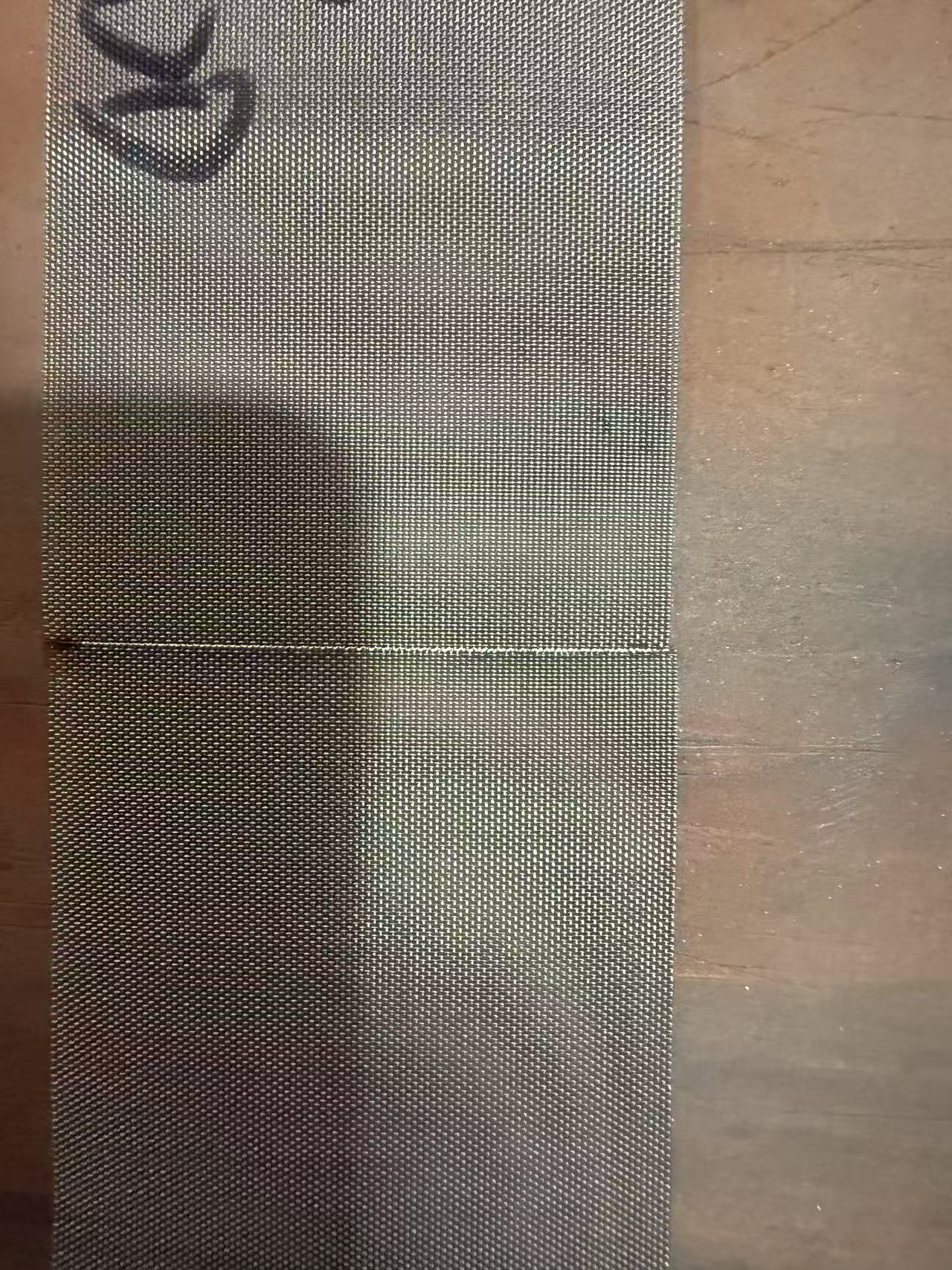

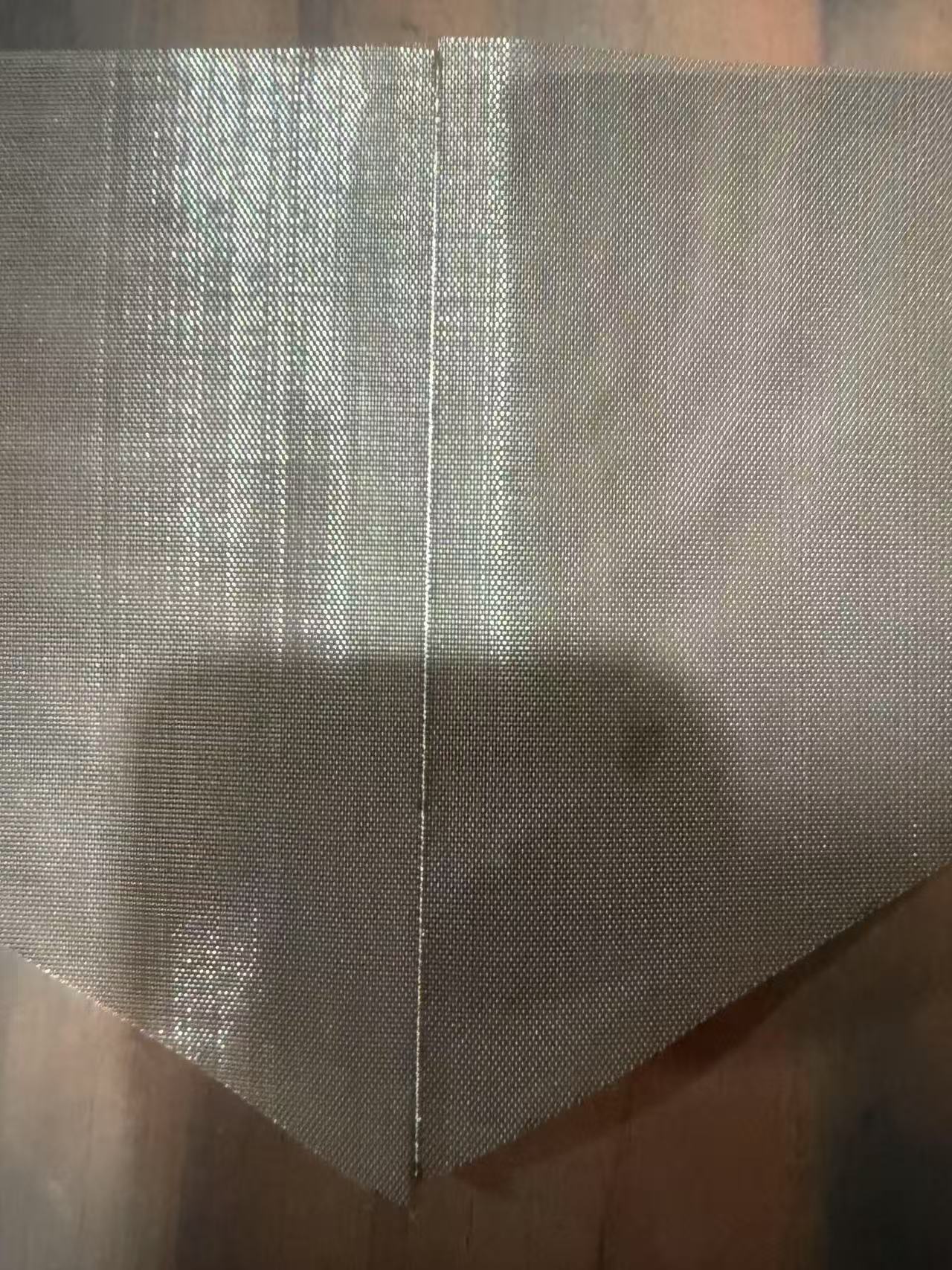

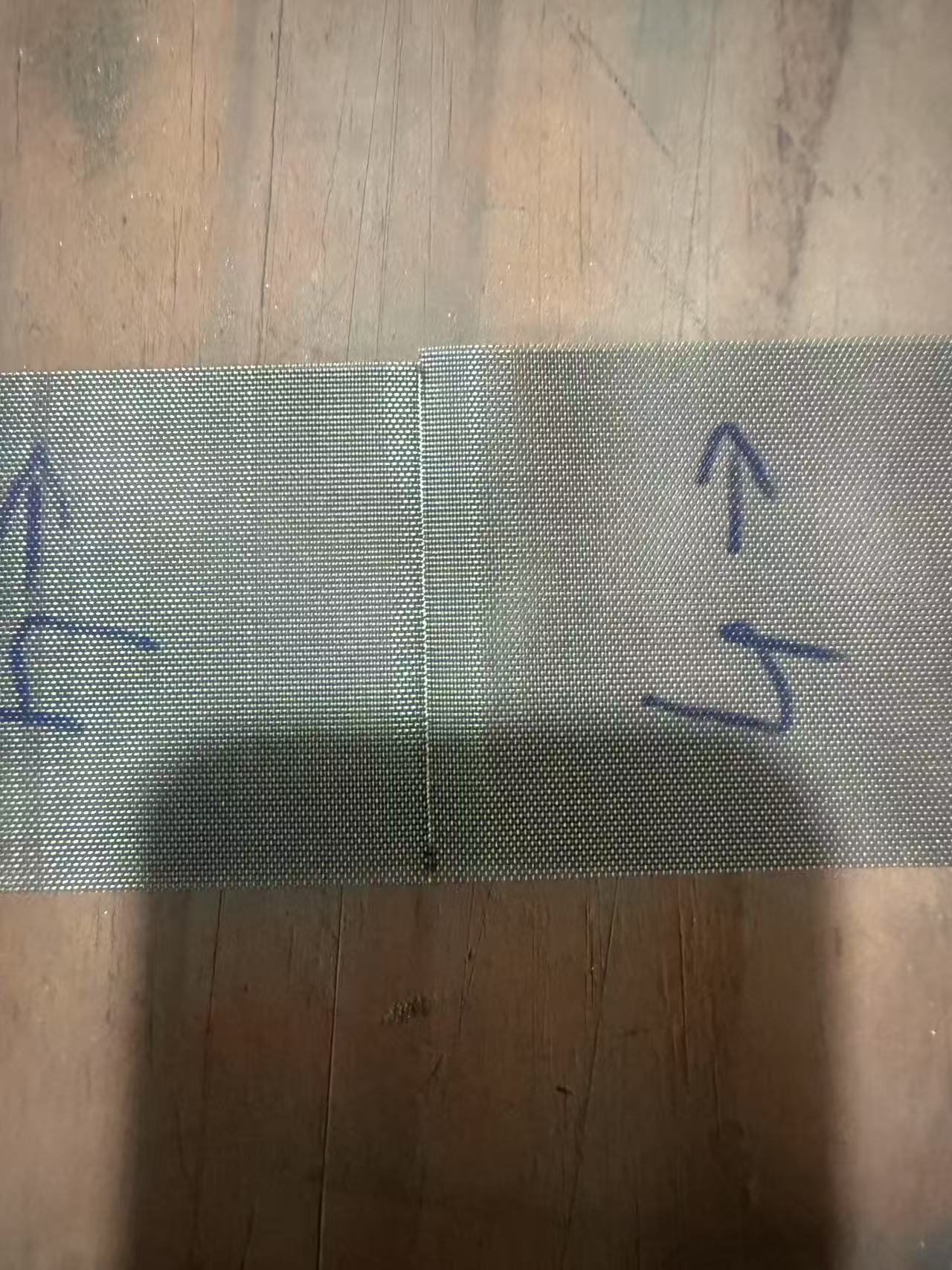

The YAG laser welding machine, with its three core advantages of high energy density, micron-level spot size, and precise heat input control, offers zero-contact, non-deformation precision welding for metal filter elements, including stainless steel and titanium alloys. It is perfectly suited for precision filter structures with aperture sizes above 0.1mm.

Technical Advantages Analysis

| Features | Value for Filter Element Welding |

|---|---|

| Ø0.1-0.5mm ultra-fine spot | Precisely avoids filter holes; controllable weld width prevents clogging of filter channels |

| Millisecond-level energy control | Heat-affected zone <0.1mm; prevents mesh wire melting and burn-through |

| Non-contact welding | No mechanical stress; protects fragile filter structures; increases yield by 40%+ |

| CCD visual positioning system | Automatically identifies filter edges; achieves precise seam alignment in multi-layer mesh welding (supports 0.05mm accuracy) |

Typical Application Scenarios

✅ Fuel filter metal mesh cores – Multi-layer stainless steel mesh ring seam sealing welding with high pressure resistance and no leakage

✅ Medical-grade titanium alloy filter elements – Biocompatible welds with no impurities, meeting GMP certification standards

✅ Chemical high-pressure filter cartridges – Airtight welding of 0.3mm ultra-thin mesh to flanges

✅ Microporous sintered filter element end caps – Dissimilar material welding between metal mesh and support rings

Process Comparison Data

| Indicators | Traditional Resistance Welding | YAG Laser Welding | Improved Efficiency |

|---|---|---|---|

| Thermal deformation | >0.2mm | <0.03mm | Reduced by 85% |

| Weld seam width | 1.2-2mm | 0.1-0.3mm | Material loss reduced by 70% |

| Production cycle | 15 seconds/piece | 8 seconds/piece | Efficiency increased by 47% |

| Airtight qualification rate | 82% | 99.6% | Scrap cost reduced by 90% |